About ERF

EWAC Reclamation Facility (ERF) specializes in critical turnkey reclamation jobs involving weld surfacing, machining, pre & post weld heat treatment with the latest technologies and up-to-date surfacing materials.

- Our Approach

- Capabilities

- Services offered

- Analysis of wear factors/ Failure Analysis.

- Simulation of welding process and metallography of weld deposits and interface.

- Formulation of welding procedure including pre, post-weld heat treatment.

- Formulation of QAP covering all stages of the reclamation process.

- Analyzing the need for fixturing and developing the same.

- Close in-process monitoring.

- More than 6 decades of experience in maintenance and repair welding.

- State-of-the-art infrastructure for wear protection & welding jobs.

- Skilled manpower.

- Experienced R&D support for innovation & improvements in providing customized solutions.

- Metal Joining

- Wear Protection

- Weld Repairs/Reclamation

- Thermal Spray

- Anti-corrosion coatings

Expertise through experience

-

10000+

Jobs executed

-

400+

Customers across major core sector industries spread in the large area provides ample space to undertake a wide range of applications.

Facilities

- Multiple Workstations for bulk – welding and steel mill roll cladding

- Welding positioner for VRM Table Liners and other critical Jobs (4mtr dia X 20 tons capacity)

- Lathes up to (9mtr between centre & 1mtr centre height)

- Host of welding equipment –

- Submerged arc welding machines

- Flux-cored arc welding machines

- Pulse MIG / TIG machines

- SMAW – inverter-based power sources

- EWAC Zupercoat arc spray set-up for wire dia 1.6mm to 4.74mm for onsite coating of Boiler tubes, Zinc, Aluminium, stainless steel Inconel coatings

- Mobile compressors with air dryers both engine driven and electric motor driven

- Grit blasting cabinet

- Mobile grit blasting equipment

- Tank rotators up to 80-ton capacity

- Acoustic chamber for thermal spray as well as gouging

- Thermal spray –

- Fully automated HP HVOF system with Robot

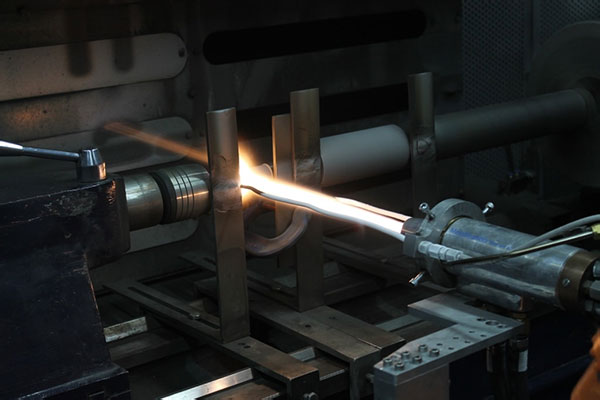

- Plasma transfer arc

Bulk Deposition Jobs

- Over 300 tons of weld Deposition experience

- Cement plant VRM Table liners, roller liners, tires, roller press rolls

- Steel plant rolls

- Coal mill rolls

EWAC Zuper Arc spray jobs (Onsite/ Workshop)

- Shafts

- Boiler Tube coating

- Industrial chimney

- Structure Aluminizing

- Zinc Coating

Flame spray

- Ceramic coating, Spray fuse (Microflow) jobs

- Carbides

- Metal alloy powder

Breakdown jobs (Onsite / Workshop)

- Forging dies

- Kiln tire

- Girth Gear

- Mill shell

- Hub

- Trunnion etc.

EWAC Teroglass anti-corrosion, efficiency increase coatings (Onsite / Workshop)

- Pumps

- Valves

- Condenser water boxes

Wear Protection Job

- Grizzly bars

- Horns

- Hammers

- Crushers

- Roller press rolls

- TRPF Rolls etc.

Related activities

- Dimensional Inspection by calibrated instruments

- NDT-UT, MPT, DPT, X-Ray

- Cylindrical Grinding

- Vertical turret lathe

- Horizontal Boring

- Long shaft machining

- Stress Relieving

- Dynamic Balancing